Our Processes

At Sunpower Electronics we understand that it is not just what the power supply is capable of, but also what we as the supplier are capable of, that customers are interested in when sourcing and developing a power supply.

This section outlines our processes and will be updated on a regular basis with details of our electronic design capabilities, product design experience and the customer support services available to you.

At Sunpower Electronics we are proud of the work we do and how we do it. This page outlines our power supply research process but if you would like more details don't hesitate to get in touch.

A successful project not only needs thoughtful planning but also requires dedication from all parties involved. When we start our power supply project planning we break down the product specification to create a project plan detailing the stages of the project, including timelines and milestones, also taking into consideration the customers own procedures for new projects and existing commitments.

The project plan will include elements to be completed by Sunpower and the customer, setting dates that elements should be submitted for approval by and approved by and highlight any dependencies that could be affected should a party not complete their element by the required date. This ensures that all parties fully understand the project and what stage it should be at, at any given time.

Once agreed we will assign a manager for the project to ensure it maintains direction and does not loose momentum through the process.

Elements we consider when constructing a project plan

- Resources - Are there any specified components with long lead-time or no second source? Availability of equipment i.e. test chambers. Manpower

- Interfaces - this includes any type of transfer between our team, you the customer and suppliers; these will be defined and agreed at the outset of any project.

- Dependencies - Work of one member of the project may depend on that of another. We will highlight these at the outset so that all are aware if the impact their particular tasks may have on others.

- Timescales - It is a common occurrence to under estimate the times required to complete elements, especially when availability of resources is not considered. We have a precise understanding of the elements required of us, from CAD design through to sample testing, to ensure that realistic dates are applied. We will work closely with the customer to glean an understanding of their resources to ensure achievable scales are set here too.

Our policy of continual improvement ensures that we regularly monitor and review our performance so that valuable information is collated and future projects may be better planned. Feedback from our customers is an integral part of this process, our ability to react quickly to customer concerns and changes in the project is key to our success.

Our product planning process

In order to systemise the process and produce results as quickly as possible it is necessary to clarify the decision making process and utilise the knowledge of our experienced engineers to analyse the design information.

Each project is assigned a single point of contact to ensure the execution of the project is as smooth as possible, this person will have a thorough understanding of the project and will conduct regular project review meetings both internally and with the customer.

1. Marketing Information/Customer Specification/RFQ

The first step is to collect the marketing information or customer specification, request for quotation and any other relevant supporting documentation. This is generally done by conducting an initial meeting where we can gain a better understanding of the requirements and obtain answers to preliminary technical and commercial questions that arise through the discussions. At this stage we will obtain key stage targets from the customer for imperative targets to them such as sampling and production runs.

2. Cost/Technology Capability Analysis

A team of design engineers, purchasers and/or application engineers will consider the requirements and analysis the feasibility of the product to determine costs and available resources. At this stage the project plan begins to establish a timetable for the project, and co-ordinating the available resources.

3. Product Plan Review

R&D, sales and/or engineering will review the project plan. The project plan is reviewed at this stage to ensure the co-ordination of customers targets, Sunpower targets and available resources. At this stage a risk analysis is also carried out to highlight any potential areas of delay to reduce the risk of issues occuring during the active project.

4. Meets Requirements?

The decision is made as to whether the cost and capacity meets with marketing or customer requirements. This is the final stage where the entire project is discussed and any areas of concern are raised before the project is agreed and is set in motion.

5. Design Group

The project is formally assigned an identification number and passed to design to carry out the next stages; working in line with the product plan.

Our policy of continual improvement ensures that we regularly monitor and review our performance so that valuable information is collated and future projects may be better planned. Feedback from our customers is an integral part of this process, our ability to react quickly to customer concerns and changes in the project is key to our success.

The power supply has often been an afterthought in the design process of an application. With the realisation of the complexities of some system design processes, the power supply is becoming more of aforethought, due to their sophistication and complex designs.

All of our factories and offices are approved to ISO 9001-2000, ISO-9001 and/or ISO-14001 ensuring quality assurance from initial concept through the power supply design process, manufacture and production of a power supply.

When starting any power supply design project the initial discussions will be based around creating or reviewing the technical specifications. Once this is agreed in principle timelines and key milestones, responsibilities, resources and dependencies will be discussed and if required, a project plan produced. Currently, the market is congested with single-use un-serviceable throwaway items, by designing many of our products to be serviceable it allows us to ensure many products have the potential to extend their working life.

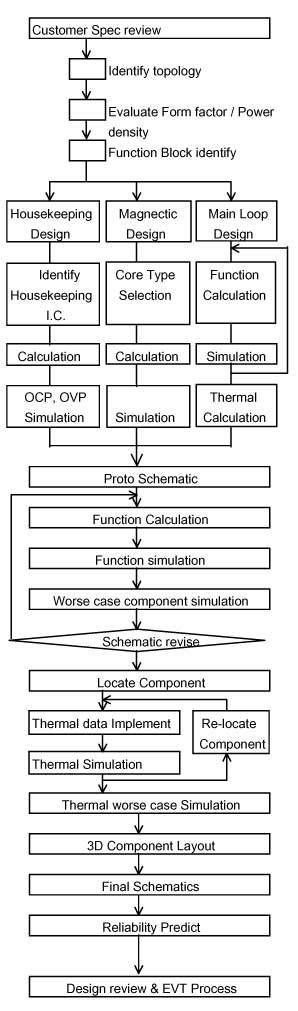

The power supply design process can go through any variation of the stages, dependant on the product type, complexity and intended application.

Require assistance in your power supply design process? Contact Sunpower!

At the outset of a bespoke project or when developing a new standard project range we tend to follow a power supply development process. Although a formal development procedure is often not appropriate for research, it can be used to provide a core development platform for several research projects. Sunpower's product development procedure can be extensive or simple depending on the requirements set out by the complexities of your product. When you engage with Sunpower you can be totally confident that you are dealing with a specialist supplier that delivers a totally integrated, cradle to grave support network.

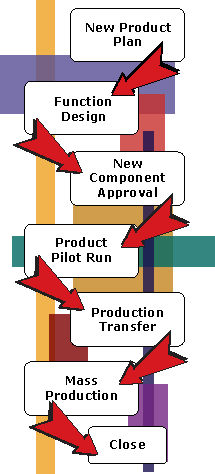

Below is an example of a product development procedure from Sunpower.

- New Product Plan

During the new product planning procedure of a power supply we will consider feasibility, costs and capacity before the design is passed onto R&D to be formalised. A clear specification, knowledgeable understanding of the requirments ensures our projects move swiftly. - Function Design Procedure

The function design procedure will consider if there are any existing products that follow a similar specification. Once this is determined the project will either proceed to EVT or DVT1 stages or move onto identifying the best technology for the product. - New Component Approval

- Product Pilot Run

- Production Transfer

As a world class power supply manufacturing facility, we have earned our reputation through ensuring all our power supply designs are vigorously tested to ensure that only the products of the very highest quality and reliability reach the marketplace. This page outlines our power supply manufacturing process but if you have any questions please get in touch.

Manufacturing Capacity

Local support from an international supplier; From initial product design, through manufacture, to after sales - Sunpower's support infrastructure guarantees you will always have the back up you need for the lifetime of your product.

- Centrally located UK headquaters in Aldermaston with 25,000 sq ft of storage space

- Sunpower - Taiwan 120 employees in 59,000 sq ft facility producing 300,000 units per month

- Sunpower - China 200 employees in 45,000 sq ft facility producing 1.2 million units per month

Reliability Testing

7 Powerful reasons why you can trust Sunpower;

- FMEA - Failure Modes and Effects Analysis (FMEA) is a procedure in product development and operations management for the analysis of potential failure modes with a system for classification by the severity and likelihood of the failures. Successful FMEA activity helps to identify potential failure modes based on past experience with similar products or processes; it enables us to design those failures out of our products with the minimum of effort and resource expenditure, thereby reducing development time and costs.

- HALT - A Highly Accelerated Life Test (HALT) determines the operating and destruct limits of a design, why those limitations exist and what is required to increase those margins. HALT, therefore, stresses products beyond their design specifications, providing our engineers with the opportunity to improve product design, increase robustness and minimize the possibility of costly warranty services and expensive product recalls after release.

- HASS - Highly Accelerated Stress Screening (HASS) builds on the results of HALT, screening every piece of production for hidden manufacturing defects and defective components.

- Thermal Modelling - Power dissipation creates hot spots which may have a detrimental effect on performance and safety.

- Salt Spray Test - An accelerated test to check corrosion resistance of finished surfaces or parts.

- Vibration Test - A product is shaken, one axis at a time, to simulate potential environmental motions and the effect they may have on energy and noise.

- MTBF - Mean Time Before Failure – The predicted elapsed time between inherent failures during operation.

As would be expected from a world class manufacturer, we have fully automated manufacturing and test facilities which ensure both consistent performance and reliability of finished products. Every product is subjected to 100% functional testing and burn in, using some of the most sophisticated manufacturing equipment available.

Sunpower's Partners

The better the players the stronger the team; Sunpower Technology LLP is approved to ISO 9001:2008 and our factories to both ISO-9001 and ISO-14001. We work in partnership with only recognised market leaders in the field’s key to our business, to guarantee that you can be confident of consistently stringent standards in all aspects of a product’s life cycle. From excellent, forward thinking design, through efficient production to total durability and reliability of use and ease of maintenance and repair, Sunpower ensure you become part of a winning team.

Bridgelux – An established leading developer and manufacturer of solid-state LED technology. Constantly growing and investing, Bridgelux introduce new LED chips approximately every 6 months with 15~20% performance improvements each time.

Cree – A leader in the solid-state lighting industry recognizing the revolutionary potential of brightness and efficiency of LED’s.

Philips – A worldwide company and brand producing highly efficient and reliable capacitors.

IOR – Power management leader – High performance analogue, digital and mixed-signal IC’s, advanced circuit devices, power systems and components. Six decades of technology leadership.

Texas Instruments – The first semiconductor company to go global whilst using an increasingly complex signal-processing technology to produce world class innovations.

ST – A world leader in pioneering semiconductor solutions with 12 manufacturing sites and advanced research & development centres in ten countries worldwide.

Luxeon – Industry leading high efficient reliable and longer-lasting LED’s, built to reduce CO² emissions and minimize new energy plant expansion.

Nippon Chemi-Con – A well-known company supplying small electronic equipment components. Established in 1993, Nippon Chemi-Con have vast technical knowledge and are proven experts in resolving technical issues and developing new products.