Custom Power Supply Metalwork Design

If you already have a design ready to go, a specification of your requirements or need our assistance to solve your installation problem we can work with you on your custom power supply metalwork. We have a network of mechanical engineering and design partners who can work in AutoCAD and Pro-E to lower product development costs and ensure a shortened design cycle for your custom power supply metalwork. Using these tools we can design anything from a mounting plate, fascia panel, power supply cover to a full enclosure to ensure our power supplies fit into your equipment just as they should.

When designing full enclosures in particular we use 3D Simulation so that you can visualise how the finished unit will look and speed up the development process. The computer aided design (CAD) 3D simulation will generate detailed imagery to assist in the customer power supply metalwork design; this will show the construction of your enclosure and simulate how it would be constructed; allowing for accurate costs and reduced design to manufacture time.

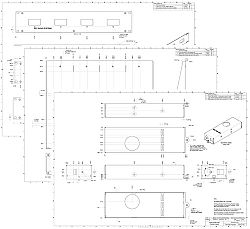

Technical mechanical diagrams, or 2D CAD drawings, will then be generated to clearly define the requirements, including dimensions, tolerances, material and finishes, for final sign off. These technical mechanical diagrams are the final stage of the custom power supply metalwork design process and contain all the information required for the unit to be manufactured.

Custom Power Supply Metalwork Sampling

This is your opportunity to test the fit with your equipment, or around our power supply to ensure there are no conflicts with any other components or wiring.

If required we then create production quality samples in the final material, with your required finish of zinc plating with colour passivate finish, powder coating, electroplating, anodising, other corrosion protection methods or any other finish you require to ensure it is just right.

Custom Power Supply Metalwork Production

When it comes to custom power supply metalwork production you have several options; for small projects we work closely with UK based metal fabrication services; for larger production requirements our far east factories would manage the production run. As part of this manufacturing process we can install the new metalwork onto our power supplies or supply to you to fit as part of your production process.

Value Added Services

With our partners we utilise computer aided design in AutoCAD or PRO E, create 3D Simulations of your product and produce sheet metal fabrications and enclosures in mild steel, stainless, aluminium and zintec. Metalwork finises include zinc plated covers with colour passivate finish, powder coating, electroplating, anodising and other corrosion protection finishes.

Sunpower can offer additional services when you purchase power supplies from us, from company branding and packaging to bar coding to help reduce time to market and handling. We have the ability to design your company branded product or packing labels in house, for your approval, so you can resell under your own brand with ease.

The majority of our standard power supplies have the capacity for small modifications or even more advanced changes or additions through our value added service. Where ever possible we will suggest an off the shelf solution, propose modifications to a product or guide you every step of the way in the design of a fully custom product. We offer power supply modification and modular power supply solutions to assist customers in front end power supply sourcing.

Our technical support extends beyond the point of purchase; we make ourselves available to customers throughout the life of their product!

Services

Bespoke power supply design can be a tough, complicated business.

We ensure that all of our power supply products are are safe and reliable.

We have been providing power supplies into a wide and varying array of market sectors and applications for over 13 years.

Insights

- Covid-19 Customer Update From Sunpower Electronics March 30, 2020

- LCM Series Bluetooth Mesh LED Driver January 8, 2020

- XLG Series Constant Power Mode LED Lighting Power Supplies May 15, 2019

- Sustaining Progression November 7, 2018

- Door Entry – Powering Smart Technologies July 23, 2018