The bricks are built like switched power supplies and consists of components such as switching transistors, switching controllers and energy storage devices. However they don’t have the input and output filter circuits.

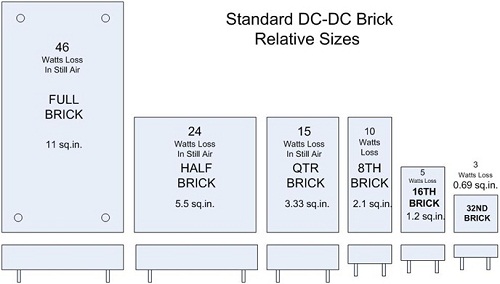

The bricks may step down or boost the input voltage and provide either, single or multiple outputs. Output power is partly determined by the physical size and design of the circuit, the full brick gives the highest power, whilst the 1/32 the least. Over the years the power density per unit area has been increasing due to the use of efficient and better switching components such as the MOSFETs.

The six standard brick sizes

1. Full brick – 4.6 x 2.4 x 0.5 inches or 116.8 x 61.0 x 12.7mm

2. Half brick – 2.3 x 2.4 x 0.35 inches

3. Quarter brick – 2.3 x 1.45 x 0.35 inches

4. 8th Brick – 1/8

5. 16th Brick – 1/16

6. 32nd Brick – 1/32

Figure 1: DOSA Standard brick sizes (Source www.edn.com)

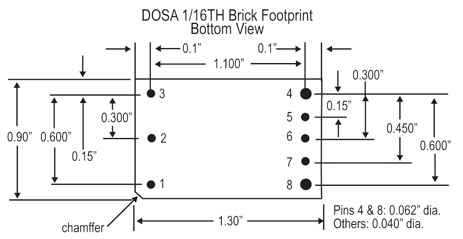

The standard power brick features include the footprints and the pin-outs, which help the designer in allocating enough space, and know how they will connect the brick outputs to the PCB circuit power inputs.

A typical 1/16 brick footprint is shown in figure 2 below:

Figure 2: DOSA dimensions for 1/16 brick. (Source: www.digikey.fi)

Advantages of power bricks

- Available from several established manufacturers

- Availability in varying standard sizes to cater for the different power requirements

- Can be replaced irrespective of the manufacturer without changing the PCB circuit design

- Customizable characteristics such as voltage, current, power and thermal management

- Equipment design engineers do not need to be experts in power supply design

- Low operating frequency of between 200 and 400 kHz hence easier to control EMI and ripple challenges

- Low cost of ownership

Drawbacks of power bricks

- It does not have input and output filters and might suffer from ripples and interference which may be undesired in sensitive equipment

- Additional components may thus be required for filtering and thermal management

- Care must be taken when mounting and they should be positioned at a location where they cannot cause electromagnetic interference problems.

- The densely packed brick generates a lot of heat and will require additional components for cooling

Uses of power bricks

- Power PCBs for industrial, military and domestic electronic equipment, game consoles

- For laptops, computers, Servers, Networking, Storage and much more