The process is supported by published derating curves and literature based on various standards. The purpose is to protect against the stresses and strength variations and prevent failures arising from the effects of small changes in operating characteristics.

Components are usually rated at high voltages and temperatures. However, applying these conditions simultaneously can deteriorate the components and lead to earlier failure.

Derating increases the average strength, decreases the average stress, and decrease the stress variations. This extends the component’s life in addition to enhancing the reliability. In power supply units, the derating is usually done in situations where operating temperatures are higher.

In electronic equipment, the derating can be done to any of the three circuit variables; namely the voltage, current or power. This creates a buffer zone between the manufacturer’s recommended maximum rating and the actual applied stress. The procedure is compulsory in some reliability standards and may involve carrying out a stress analysis of the component to determine the derating guideline.

Since most components are rated at ambient temperatures and free air, a change in any of these conditions such as putting the components in a sealed case or in a hot environment, the component must be derated down and operated at lower levels than the component(s) rated values. This prevents stressing and deteriorating of the components in addition to prolonging its life.

Derating involves running the system or component at a lower voltage or current and therefore less heat being generated. And can be applied to almost all the electronic components including resistors, diodes, transistors, thyristors, LEDs ICs, CPUs capacitors and others.

Derating guidelines and curves

Derating follows the standards from component or equipment manufacturers, the military, or any other agency.

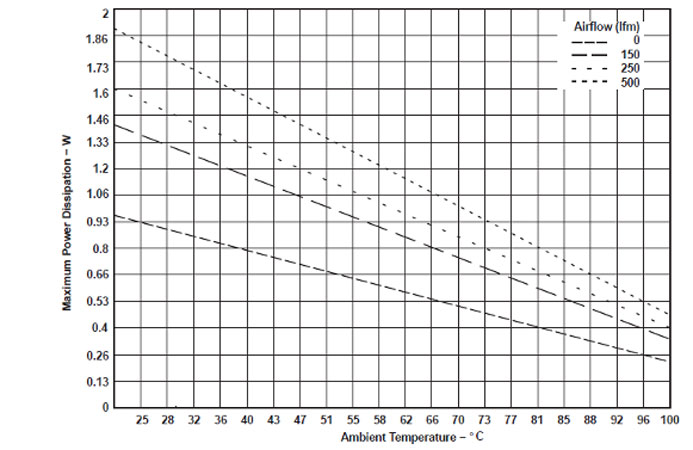

The derating curve for semiconductor components is usually based on the junction temperature which usually runs hotter than the case and the ambient. Derating curves developed for each component allow a user to see the maximum power dissipation over a range of operating conditions. One should thus understand the conditions such as the ambient temperature and airflows likely to be experienced and ensure that the appropriate derating is implemented to ensure reliability and long life of the equipment or components.

The derating curves act as a guide when determining the maximum power dissipation at various ambient temperatures. These curves are generated from calculations of the maximum power based on the thermal resistance values at different airflows.

Figure 1: Derating curves for 16-Pin SOIC (DW) Package – Image credit: Texas Instruments

Different curves with the corresponding airflows can then be plotted to help one decide the safe operating parameters at various airflows.