Since then, voluntary and then mandatory regulations have grown to ensure higher average energy efficiency of external power supplies. These initiatives have addressed both operating energy efficiency and no-load power drain. While this regulatory development has achieved real reductions in global power consumption, its somewhat explosive expansion has also created challenges for power supply and OEM manufacturers as they endeavour to keep pace with the rate of change.

This Guide describes the current state of international legislation, and how it translates into specifications that external power supplies must meet. It gives examples of new power supplies that comply with the latest efficiency standards, together with some case studies that show how high-efficiency EPSs are now being designed into a widely diverse range of industries and applications.

The first mandatory standard related to the energy efficiency of external power supplies and no-load power draw was implemented by the Californian Energy Commission (CEC) in 2004 to address power consumption efficiency on its local grid. Since then, different organisations worldwide have continuously evolved standards to further tighten regulation and improve electrical efficiency. In 2007, the US Congress passed the Energy Independent Security Act (EISA), called Level IV, to harmonise power standards across the US. EISA Level V appeared in 2011, then the US Department of Energy (DoE) published its more stringent Level VI standard in 2014. This became mandatory within the US on February 10, 2016.

The European Union enacted ErP (Energy Related Products) Eco-Design Directive 2009/125/EC in 2009, planning to harmonise with CEC and EISA by April 2011. The Directive is now at Phase 2, which applies to any product placed on the market after 27 April 2011; Phase 2 is in harmony with EISA Level V. It is expected to be upgraded to Stage 3 to meet US levels in 2017. Natural Resources Canada has implemented a Tier 1 standard, equivalent to EISA Level IV. In 2006, Australia implemented a Minimum Performance Energy Standard (MEPS), equivalent to Level III; they upgraded this in 2008 to include a voluntary High Efficiency category equivalent to Level IV.

While the United States is currently the only government to enforce compliance to the Level VI standard, most external power supply manufactures outside the US are also working to meet these requirements. Level VI compliance elevates a product to a universal power supply platform guaranteed to meet or exceed the requirements of any governing body around the world – a critical requirement for any OEM committed to shipping their products globally.

Power supply manufacturers indicate compliance by placing a Roman numeral (I, II, III, IV, V or VI) on the power supply label as specified by the International Efficiency Marking Protocol for External Power Supplies Version 3.0, updated in September 2013.

The DoE EISA Level VI standard

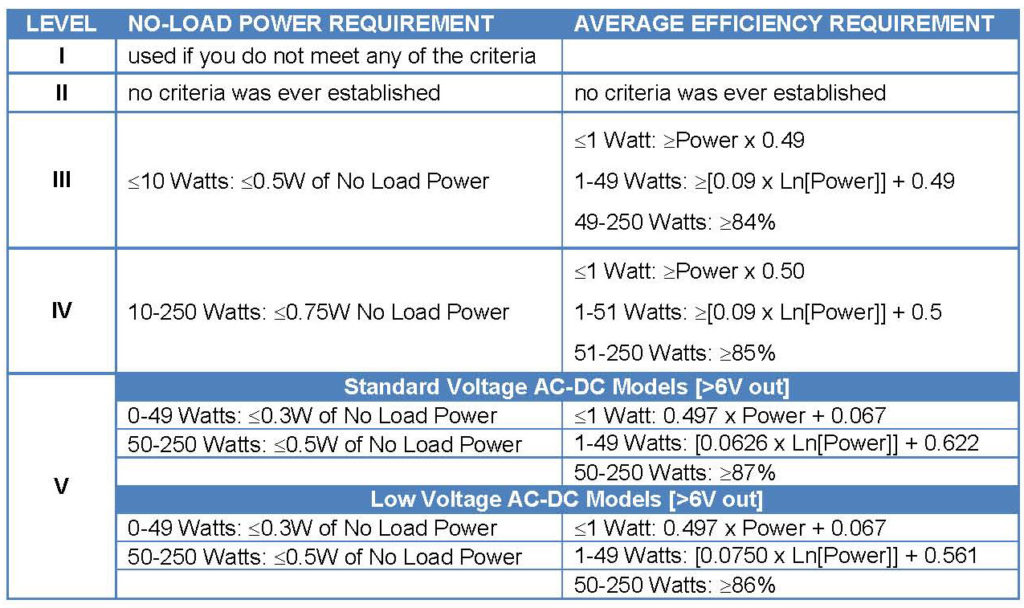

Fig.1 below shows the earlier versions from which level VI is derived. Appreciation of these earlier standards, particularly Level V, is important as they provide the platform on which Level VI is built.

By comparison to Level V, the Level VI standard tightens performance thresholds not only for adaptors in active mode, but also during no-load conditions. Additionally, it expands the range of products covered, so regulated products now include:

- Multiple-voltage external power supplies

- Products with power levels >250 watts

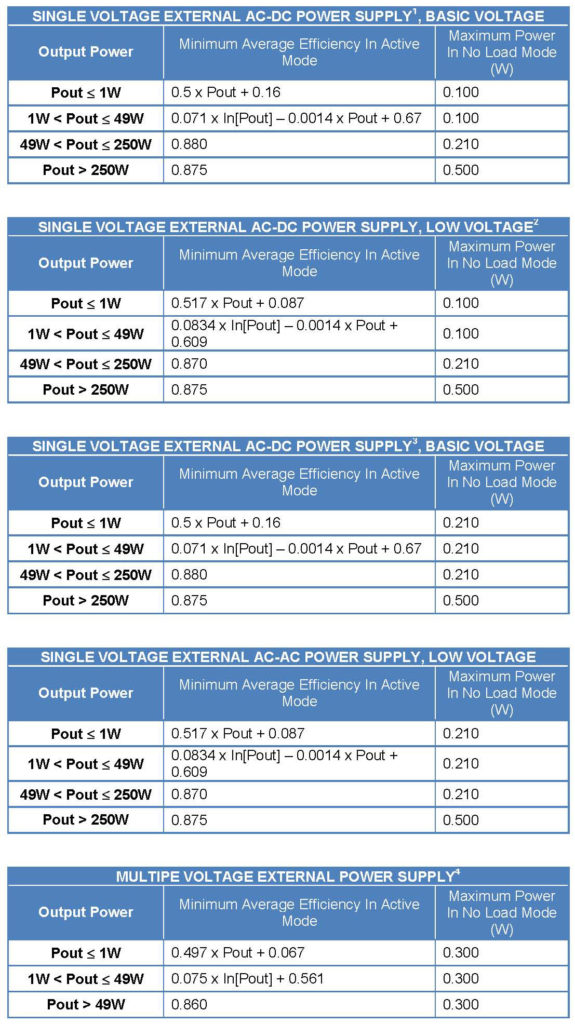

Overall Level VI performance thresholds are summarised in the tables below:

The following Notes apply to the tables in Fig.2:

- Single-Voltage External Ac-Dc Power Supply

An external power supply that is designed to convert line voltage ac into lower-voltage dc output and is able to convert to only one dc output voltage at a time. - Low-Voltage External Power Supply

An external power supply with a nameplate output voltage less than 6 volts and nameplate output current greater than or equal to 550 milliamps. Basic-voltage external power supply means an external power supply that is not a low-voltage power supply. - Single-Voltage External Ac-Ac Power Supply

An external power supply that is designed to convert line voltage ac into lower-voltage ac output and is able to convert to only one ac output voltage at a time. - Multiple-Voltage External Power Supply

An external power supply that is designed to convert line voltage ac input into more than one simultaneous lower-voltage output.

Further Level VI definitions

Direct vs Indirect operation: Level VI classifies power supplies as either direct operation or indirect operation products. A direct operation product is an external power supply (EPS) that functions in its end product without the assistance of a battery. An indirect operation EPS is not a battery charger but cannot operate the end product without the assistance of a battery. The new standard only applies to direct operation external power supplies. Indirect operation models will still be governed by EISA2007- defined limits.

Level VI exemptions: The Level VI mandate defines exemptions for EPS products. The direct operation EPS standards do not apply to:

- Products that require Federal Food and Drug Administration listing and approval as a medical device in accordance with section 360c of title 21;

OR

- Direct operation, ac-dc external power supplies with a nameplate output voltage less than 3 volts and nameplate output current greater than or equal to 1,000 milliamps that charges the battery of a product that is fully or primarily motor operated.

Level VI and legacy products: Compliance eligibility is based on the date of manufacture within the United States, or date of import into the country. Accordingly, legacy products can still be shipped provided the US manufacture or import date is earlier than 10 February 2016.

Level VI – compatible power adaptors

The stringency of Level VI compared with Level V has meant significant adaptor design changes and challenges to power supply manufacturers, while OEMs require Level VI products to maintain a Green image, minimise power consumption and retain access to their worldwide markets. Fortunately, Level VI-compliant products are now available, as exemplified by the two recently-announced Mean Well green adaptor series described below.

Level VI-compliant example #1: Mean Well GE12/18/24/36 series

Level VI-compliant example #2: Mean Well GST18/25/36 Series

Level VI-compliant example #3: Mean Well GST160A/220A/280A Series

These three new Series complement the existing GST40A/60A/90A/120A (40 – 120 W) line to present a complete new-generation green power adaptor family ranging from 12 to 280 W. Every family member is fully compliant with EISA 2007/DoE Level VI energy efficiency regulations.

The GST18/25/36 Series comprises two types – Desktop (A/B) and Wall Mounted (E/U), while the GST160A/220A/280A Series provides 160/220/280 W and meets OEM demands for higher-power adaptors.

Both the working efficiency and no-load power consumption of these new Series are much better than those of earlier Level V compatible versions that have been available for many years. The products are well-suited to consumer electronics and telecommunications equipment devices, office, commercial and industrial equipment, and all types of apparatus or systems requiring conformity to the latest energy-related regulations.

The new products accept 85 – 264 VAC (127-370VDC) input, with an ultra-low no-load power consumption of less than 0.15 W. (GST/18/25/36 < 0.075 W, GST280A < 0.5 W). Full compliance includes NRCan, AU/NZ MEPS, EU ErP and CoC Version 5 as well as EISA 2007/DoE Level VI. Other approvals include UL / CUL / TUV / BSMI / CCC / PSE / CB / FCC / CE/BIS and Pass LPS.

A 94V-0 flame retardant plastic case, together with free air convection cooling, allows a -30°C to +70°C working temperature range. Short circuit, over voltage and overload (plus over temperature on some models) protections are provided, as well as a Power On LED indicator.

Applications examples

Sunpower has been delivering new-generation high-efficiency power products into a widely diverse range of applications. These adaptors give significant marketing advantages to their OEM users, because in addition to their energy efficiency credentials, Sunpower has customised them in various ways to meet specific application conditions; saving space, cost or time to market.

In a pro broadcast application, for example, a high reliability, cost-effective power adaptor in a small footprint has a customised DC connector and tailored EMC performance while meeting DOE Level VI efficiency criteria. An ePOS/mPOS application similarly benefits from a customised power adaptor that complies with energy efficiency guidelines even while providing a high current output at 5 V.

Other applications include commercial and 3D printers, stage, screen, photography and lighting, and computer peripheral switches for banking applications. Products have been modified to provide custom output connectors and pin assignments, support for continuously varying resistive and capacitive loads, high reliability, tailored EMC performance, high operating temperature ranges and small form factors.

Conclusions

Increasingly stringent and mandatory energy efficiency regulations present significant challenges to power supply manufacturers and OEMs alike. However they are essential and have been effective in eliminating billions of kilowatts of power wastage and millions of tons of CO2 emissions per year.

The regulatory climate also offers more immediate opportunities to OEMs, especially if they partner with capable, well-resourced and experienced adaptor suppliers like Sunpower. Sourcing Level VI-compliant adaptors eases access to market internationally, with a competitive edge further reinforced if the products have been customised to OEMs’ exact requirements.