What is Power Factor Correction?

The power factor correction is a technique of increasing the power factor of a power supply. Switching power supplies without power factor correction draw current in short, high-magnitude pulses. These pulses can be smoothed out by using active or passive techniques. This reduces the input RMS current and apparent input power, thereby increasing the power factor.

The power factor correction shapes the input current in order to maximize the real power from the AC supply. Ideally, electrical equipment should present a load that emulates a pure resistor, meaning that the reactive power would be zero. And the current and voltage waveforms would be the same sine wave and in phase with one another. However, due to the reactive components in a majority of circuits, there is always a power lag that leads to lower power factors.

In an ideal system, all the power drawn from the AC mains is utilized in doing useful work. This is only possible when the current is in phase with the voltage. When the phase between the two varies, some of the energy from the AC outlet does not perform useful work and is lost.

The power generating company must therefore produce more power to meet the demand for the useful power and the one that is lost. This means more capital investments in generation, transmission, distribution and control. The costs are passed on to the consumer in addition to contributing to global warming.

Power factor correction tries to push the power factor of the electrical system such as the power supply towards 1, and even though it doesn’t reach this it gets to as close as 0.95 which is acceptable for most applications.

Power factor correction methods

There are two common types of power factor correction for power supplies; the passive PFC and the active PFC.

Passive Power Factor Correction

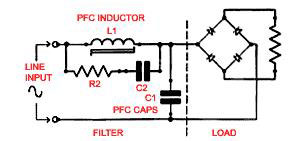

This is used for small power supplies of about 100W or less. The correction method uses a low pass harmonic filter at the AC input with the capacitor and inductor forming a series resonance circuit. The components can be fairly small while providing an inexpensive and efficient power factor correction.

Figure 1: A Passive PFC Image Credit

The passive PFCs are simple, robust and reliable for lower power requirements. In addition, they do not generate EMI. However, they are big and heavy due to the inductor.

Advantages

- Inexpensive

- Efficient

- Simple construction

Disadvantages

- Heavy and large size

- No voltage regulation

- Limited range of input voltages

Active Power Factor Correction

The active PFC methods are preferred for power supplies of over 100W. This method provides a more efficient correction, is lighter and less bulky.

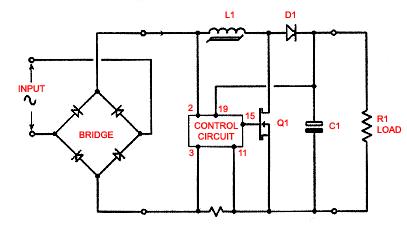

A basic active PFC circuit consists of a control circuit that measures the input voltage and current and then adjusts the switching time and duty cycle to ensure that the input voltage and current are in phase. This provides an automatic correction of the input AC voltage, resulting to a theoretical power factor of over 0.95. Unlike the passive PFC, the active PFC operates over a wide range of input voltages. However, it requires extra components, which makes it more complex and expensive.

Figure 2: The Basic Active PFC Circuit Image Credit

Advantages of an Active PFC

- Attains PF of 0.95 or higher

- Small and light

- Wide range of AC input voltage and frequency (87 Vrms -266 Vrms and 47Hz- 63Hz).

- More flexible

- Greater control

Disadvantages

- Complex

- Higher cost

- Requires more filtering because of the high frequencies which can get into the line

- Components are rated at higher voltages compared to the passive PFC.

Benefits of PFC

With power factor equal to 1 or as close as possible, there are lower losses and all power generated is utilized efficiently.

- The technical benefits: Improved efficiency and reduction in power demand, hence a reduction in the load on the switching gear and cables, reduced costs to the consumer and support for more load.

- Commercial benefits: There are reduced system losses and less capital cost for the generating company. In addition, there are saving on electricity costs, since there are no charges for the excess reactive power. Another benefit is that the transmission and distribution equipment and systems runs cooler and last longer.

- Environmental benefits: reduced CO2 emissions.